The Dangerous Landscape of Industrial Refuse

Types of Hazardous Waste

Throughout various industrial processes, waste generation can lead to several types of hazardous waste. You may encounter four main categories: ignitable, corrosive, reactive, and toxic. For instance, ignitable materials include certain solvents and oils that catch fire easily. The Environmental Protection Agency (EPA) reported that in 2019, almost 24 million tons of hazardous waste were produced in the United States alone, indicating the scale and potential risk associated with improper disposal.

Health Risks Attached to Industrial Waste

Exposure to inadequate disposal methods can expose workers and communities to a plethora of health risks. Toxic substances, like heavy metals and chemicals, can culminate in chronic illnesses, ranging from respiratory issues to severe neurological damages. For example, studies have shown that long-term exposure to lead and mercury, common in electronic waste, significantly increases the risk of organ damage and cognitive impairments. You must be aware of how these risks affect not only employees but also local ecosystems.

Environmental Consequences

Your local environment isn't immune to the repercussions of industrial refuse. Improperly stored waste might seep into the soil and water supplies, leading to contamination that could persist for decades. The infamous Love Canal catastrophe in the late 1970s showcased this danger, where toxic waste buried beneath a neighborhood precipitated alarming health crises among residents. Over 800 families were forced to evacuate, illustrating how quickly industrial refuse can evolve from a hidden problem to a public health emergency.

The Role of Regulation and Compliance

Regulatory frameworks exist to mitigate the dangers associated with industrial waste. Agencies like the EPA enforce strict guidelines for waste management, providing you with guidelines tailored to your specific industry needs. Programs for waste management, like the Resource Conservation and Recovery Act (RCRA), allow for structured oversight, helping ensure that your company's waste disposal practices align with federal standards. Compliance isn't just about following the law; it significantly minimizes risk to your operation and the surrounding community.

Innovative Solutions and Best Practices

Advancements in technology and best practices are reshaping how industries manage waste, allowing you to take a proactive approach. Techniques like waste minimization and source reduction not only help reduce the amount of dangerous industrial refuse generated but also lead to substantial cost savings. Implementing recycling processes and utilizing green technologies helps transform waste into resources, reducing environmental impact while enhancing sustainability efforts. Companies that adopt these practices not only comply with regulations but also gain a competitive edge.

Engaging in robust waste management strategies can safeguard your workforce, community, and environment against the ongoing dangers posed by industrial refuse. Staying informed and proactive allows you to shape a secure, sustainable future for your operations.

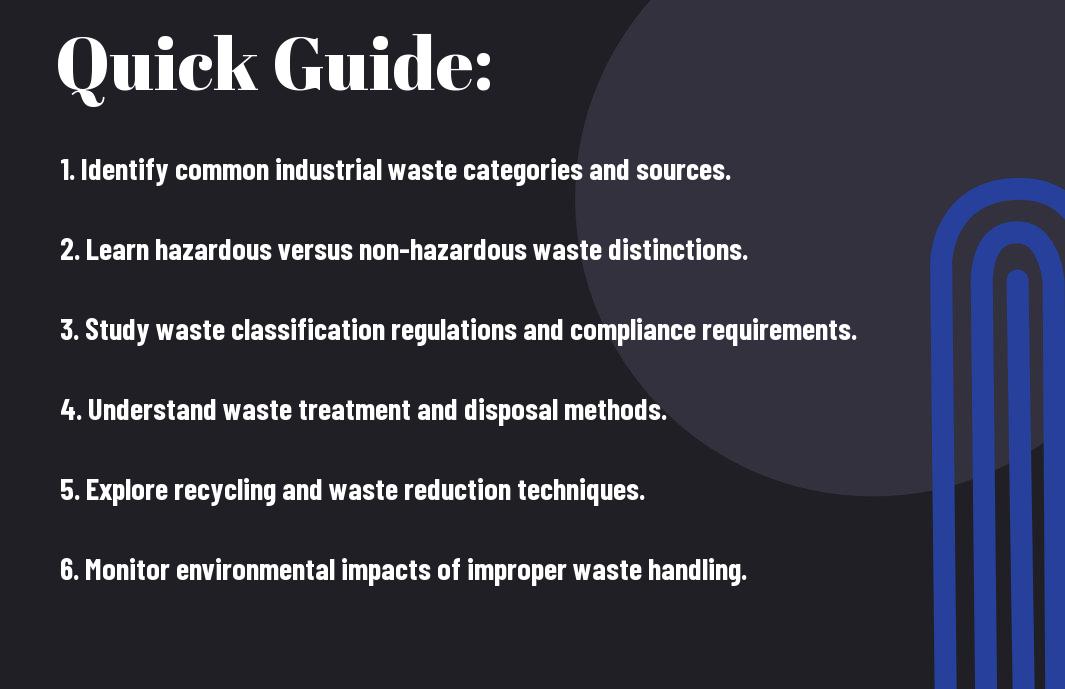

Key Takeaways:

- Various types of industrial waste include hazardous, non-hazardous, solid, liquid, and biomedical waste, each requiring different management strategies.

- The classification of industrial refuse is vital for compliance with environmental regulations and for developing effective waste management and recycling programs.

- Understanding the properties and potential risks of different waste types helps in mitigating negative impacts on human health and the environment.

- Effective waste disposal methods can involve recycling, incineration, landfilling, or treatment processes based on the waste type and applicable regulations.

- Stakeholders, including industries and regulatory bodies, must collaborate to improve waste management practices and promote sustainable solutions.

Decoding the Components: Chemical, Biological, and Physical Waste

Hazardous Chemicals: Recognizing the Warning Signs

Identifying hazardous chemicals in industrial waste is vital for maintaining safety in your operations. Look for labels indicating toxicity, corrosiveness, or flammability, and be aware of any odors that signal the presence of volatile substances. Understanding the MSDS (Material Safety Data Sheets) for materials you handle will equip you with critical knowledge about potential risks and necessary precautions. Proactive recognition of these signs helps prevent potential accidents and allows for proper handling and disposal methods.

Biological Waste: From Contamination to Biodegradation

Biological waste encompasses a range of organic materials that can cause contamination if not managed properly. You may encounter items like food scraps, plant materials, and even medical waste, all of which can lead to pathogen growth if not treated accordingly. The process of biodegradation plays a pivotal role in breaking down these materials into less harmful substances.

This breakdown is facilitated by microorganisms that thrive on organic waste, converting it into carbon dioxide, water, and nutrient-rich compost. Proper disposal and segregation of biological waste are vital. For instance, separating biodegradable waste in your facility not only minimizes the risk of contamination but also allows for advantageous practices like composting, which can enhance soil quality and promote sustainable waste management methods.

Physical Waste: The Impact of Solid and Mixed Materials

Physical waste comprises solid and mixed materials that can pose significant challenges in disposal and recycling efforts. Items like metals, plastics, and construction debris require particular attention, as they contribute to environmental pollution if discarded improperly. Understanding the composition of your waste stream will help you implement strategies for efficient management and sustainable practices.

The impact of physical waste extends beyond simple disposal; it affects the entire lifecycle of materials. For example, the improper management of construction debris can lead to large volumes of waste filling landfills, where they remain for decades. Implementing sorting and recycling protocols not only reduces the volume of physical waste but also promotes the reuse of valuable resources, contributing to a circular economy. Maximizing resource recovery can lead to significant financial savings for your operation while also benefiting the environment.

The Environmental Ripple Effect: How Industrial Waste Affects Ecosystems

Soil Contamination: The Silent Thief of Fertility

Industrial waste often seeps into the soil, introducing toxic substances that compromise its nutrient content and detrimentally affect the biological activity imperative for plant growth. Heavy metals, chemicals, and petroleum products can create irreversible damage, reducing fertility and rendering lands unfit for agricultural use, thereby threatening food security.

Water Pollution: The Poisoning of Aquatic Life

Water sources receive the brunt of industrial waste, leading to the contamination of rivers, lakes, and oceans. Toxic substances such as heavy metals, oil spills, and hazardous chemicals disrupt aquatic ecosystems, endangering species and affecting the food chain.

Fish and other aquatic organisms encounter toxic conditions exacerbated by elements like mercury and lead, which accumulate in their tissues over time. This bioaccumulation not only threatens the survival of local fish populations but also compromises the health of humans who depend on these water bodies for their livelihoods and nutrition. Disruptive algae blooms, fueled by nutrient runoff from industrial activities, further stifle aquatic life by depleting oxygen levels in the water, creating dead zones where few organisms can survive.

Air Quality: Emissions and the Health of Communities

Airborne emissions from industrial activities introduce pollutants that can significantly degrade air quality, impacting both human health and environmental integrity. Communities situated near industrial zones experience increased risks of respiratory illnesses, cardiovascular problems, and other serious health issues attributable to the inhalation of harmful particles.

Exposure to volatile organic compounds (VOCs), sulfur dioxide, and particulate matter affects vulnerable populations, notably children and the elderly. Long-term studies have shown that individuals living within proximity to industrial emissions not only face a higher incidence of asthma but also increased mortality rates linked to pollution-related health conditions. Your community's health can directly suffer from neglecting proper waste management practices, making it imperative for industries to adopt safer operational standards and invest in cleaner technologies.

Regulatory Frameworks: Navigating the Legal Labyrinth

Key Legislation: Understanding EPA Guidelines

Familiarity with the Environmental Protection Agency (EPA) guidelines ensures your operations comply with established standards. Key legislative acts, such as the Resource Conservation and Recovery Act (RCRA), govern the treatment, storage, and disposal of hazardous waste. Understanding the classification of waste under RCRA—such as characteristic wastes and listed wastes—is vital for any industrial entity aiming to navigate compliance seamlessly.

Compliance Challenges: Obstacles Industrial Entities Face

Navigating regulatory compliance can be overwhelming, particularly with constantly evolving legislation. Industrial entities often encounter financial strains arising from the need to invest in environmentally sustainable practices and technology upgrades. Additionally, staff training demands further resources to ensure proper management of industrial waste, complicating compliance efforts.

Adherence to environmental regulations often leads to complexities that require balancing operational efficiency with compliance responsibilities. You may face delayed project timelines due to the need for environmental reviews or struggle with the costs of implementing adequate waste management systems. The ever-changing regulatory landscape adds to this pressure, making it difficult to stay informed about new standards or amendments, which could potentially expose your operation to penalties.

International Norms: A Global Perspective on Industrial Waste

Global treaties, such as the Basel Convention, play an influential role in shaping international norms around industrial waste management. You should be aware that these agreements establish guidelines for the transboundary movement of hazardous waste, compelling you to adopt responsible waste management practices that reflect international standards.

Awareness of international norms can enhance your compliance strategies and improve environmental stewardship across borders. For instance, adherence to the OECD waste policies can bolster your reputation in markets where sustainability is prioritized. Engaging in global best practices not only mitigates legal risks but may also attract investment or partnerships that favor environmentally conscious practices, demonstrating proactive leadership in sustainable industrial operations.

Innovative Technologies: The Future of Waste Management

Waste Minimization Strategies: Reducing the Source

Identifying opportunities for waste minimization involves assessing your production practices and supply chain management to find ways to reduce the amount of waste generated at its source. You could implement lean manufacturing techniques or process redesigns that emphasize efficiency and resource conservation, helping to mitigate waste before it starts.

Recycling Revolution: Transforming Refuse into Resources

The recycling revolution is fundamentally changing how industries approach waste management. By integrating advanced sorting technologies and materials recovery processes, your organization can reclaim valuable materials from industrial refuse, converting them into usable resources. This not only conserves natural resources but also significantly minimizes landfill dependence.

For instance, some manufacturing companies have embraced closed-loop recycling systems where waste materials are brought back into production cycles. This practice results in a marked decrease in raw material costs and boosts sustainability. A notable example is the automotive industry, where parts made from recycled metals and plastics are now commonplace. Through innovation, the recycling revolution is illustrating that waste can be transformed into a resource rather than a liability, cultivating a sustainable and economically viable future.

Waste-to-Energy: Harnessing Energy from Refuse

Waste-to-energy technologies are becoming increasingly popular as you look for ways to convert non-recyclable waste into usable energy. Through processes like thermal treatment or anaerobic digestion, waste can be transformed into electricity, heat, or fuel, thereby providing an effective alternative energy source.

Investing in waste-to-energy facilities allows you to capitalize on the energy potential of organic and non-organic materials. For example, in countries like Sweden, waste-to-energy plants power millions of homes while simultaneously reducing landfill waste drastically. These systems not only help in energy production but also play a vital role in lowering greenhouse gas emissions, showcasing a powerful synergy between waste management and sustainable energy solutions.

The Role of Corporate Responsibility: Beyond Compliance

Sustainability: A New Business Paradigm

Integrating sustainability into your business model extends beyond regulatory compliance; it shapes a new competitive edge. Companies that prioritize sustainable practices not only fulfill environmental responsibilities but also capitalize on consumer trends shifting towards eco-friendliness. This shift can lead to increased brand loyalty, potentially boosting profits through innovative waste reduction techniques and recycling initiatives.

Stakeholder Engagement: Building a Waste-Savvy Workforce

Engaging your employees and stakeholders in waste management processes cultivates a culture of responsibility and innovation. Involving your workforce in sustainability initiatives can lead to significant waste reduction, as employees often have unique insights and ideas on improving waste management systems.

Encouraging your team to participate in training programs and workshops focused on waste management fosters a deeper understanding of industrial waste types and their effects. Providing incentives for innovative waste solutions not only empowers your workforce but also aligns them with your company goals, ultimately enhancing operational efficiency and creating a more environmentally conscious workplace.

Transparency and Accountability: The Ethics of Waste Management

Adopting an ethical approach to waste management demands transparency and accountability at every level of your organization. Openly sharing waste management practices and outcomes with stakeholders builds trust and enhances your reputation within the community.

By publicly reporting on your waste generation and disposal practices, you create an environment where stakeholders can hold your organization accountable. For instance, sharing your annual waste audit results can drive significant improvements and encourage community dialogue about responsible industrial practices. This level of transparency not only improves your company's credibility but also drives industry-wide improvements in waste management ethics.

Practical Solutions for Modern Industries: Best Practices and Strategies

Conducting Waste Audits: Assessing the Realities

Conducting comprehensive waste audits allows you to assess your production processes and identify the types and volumes of waste produced. This hands-on approach highlights inefficiencies, enabling you to develop targeted strategies for waste reduction and recycling. A thorough audit empowers you with valuable data that will inform your waste management decisions and foster a culture of continuous improvement within your organization.

Employee Training Programs: Shaping a Culture of Responsibility

Implementing robust employee training programs establishes a foundation for environmental stewardship within your workforce. These programs should focus on waste minimization techniques, proper disposal methods, and the importance of adhering to regulatory practices. By educating your team, you promote accountability, ensuring that every employee recognizes their role in managing industrial waste effectively.

Integrating hands-on workshops and regular training sessions can significantly enhance employees' engagement with waste management policies. Use real case studies to illustrate the tangible impacts of waste reduction on both the environment and the company's bottom line. Encourage employees to share their ideas for improving waste practices, fostering a sense of ownership and commitment to environmental sustainability throughout your organization.

Collaboration with Environmental Organizations: Strength in Numbers

Partnering with environmental organizations can amplify your waste reduction efforts, providing access to expert resources and innovative practices. Collaborating with these groups enables you to stay informed about the latest trends in waste management, sustainability initiatives, and regulatory changes. This relationship not only enhances your corporate reputation but also drives meaningful change in your operations.

By participating in collaborative networks, you can share experiences, tools, and best practices with others in your industry, ultimately improving collective waste management outcomes. Engaging in joint initiatives, such as community cleanup events or recycling drives, can further demonstrate your commitment to sustainability and environmental protection. These partnerships can facilitate knowledge-sharing and drive innovation, ensuring your company remains at the forefront of sustainable practices in the industrial sector.

The Human Impact: Health Risks and Community Awareness

Workers at Risk: Occupational Health and Safety

Industrial workers face significant risks due to exposure to hazardous waste. Chemicals such as solvents, heavy metals, and carcinogens can lead to respiratory issues, skin disorders, and long-term conditions like cancer. You must be aware of safety protocols and personal protective equipment (PPE) designed to mitigate these dangers.

Community Education: Advocating for Awareness and Change

Effective community education initiatives highlight your role in preventing industrial waste hazards. Through workshops and outreach programs, you can understand the implications of waste in your environment and advocate for sustainable practices.

Building proactive community education fosters an informed populace, encouraging local engagement in sanitation practices. Regular workshops and town hall meetings provide you with imperative information about the types of industrial waste and their impact. This awareness cultivates a spirit of responsibility, prompting action against pollution sources while rallying support for local policy changes and environmentally friendly initiatives.

The Mental Toll: Environmental Justice in Vulnerable Populations

The strain of living near industrial facilities piles pressure on vulnerable populations, leading to increased anxiety and stress. Your mental health can be significantly affected when facing environmental hazards with little control over your situation.

The psychological burden of environmental injustice can manifest in various forms, such as chronic stress, depression, and a sense of helplessness. Communities exposed to industrial waste often experience disparities in mental health outcomes compared to those in cleaner environments. You may find it imperative to build supportive networks and advocate for resources that address both mental health and environmental quality, highlighting the need for equity in environmental health policies.

The Economic Costs of Neglected Waste: A Financial Perspective

Cleanup Costs: The Burden on Industry and Taxpayers

Neglected industrial waste leads to hefty cleanup costs that can significantly impact both your business's bottom line and taxpayers. When waste spills or contamination occurs, industries may face fines, legal fees, and the expensive process of remediation. Often, local governments are forced to allocate public funds for recovery efforts, creating a ripple effect of financial strain that doesn't just stay with you but also extends to your community.

Brand Reputation: The Price of Negligence

Neglecting waste management can tarnish your brand reputation, leading to a decline in customer trust and loyalty. Companies found to be negligent in handling industrial waste often face public backlash, potentially resulting in decreased sales and long-term damage to brand integrity. You might not realize it, but a single incident can lead consumers to rethink their purchases, impacting your market position.

Customer trust is a cornerstone of any successful brand, and when you fail to responsibly manage industrial waste, the consequences can be dire. Companies like BP suffered tremendous financial losses due to environmental crises, showing just how quickly a brand can fall from grace. Once negative perceptions take root, potential customers may hesitate to engage with your business, costing you both revenue and market share as you try to recover from the damage.

Long-term Economic Viability: The Case for Sustainable Practices

Implementing sustainable waste management practices is imperative for your long-term economic viability. Companies that prioritize sustainability often see a reduction in operational costs, increased efficiency, and enhanced customer loyalty. By minimizing waste and maximizing resource recovery, you align your business with modern consumer values that favor environmentally responsible brands.

Investing in sustainable practices yields both immediate and future economic benefits. For example, transitioning to more eco-friendly materials not only reduces waste disposal costs but can also qualify your business for tax incentives. As regulations around waste management become stricter, adopting sustainable approaches ensures compliance and avoids potential penalties. Ultimately, failure to adopt these practices can leave your business struggling to compete, while forward-thinking companies thrive in a market that increasingly values sustainability.

Conclusion

Following this comprehensive guide on industrial waste types, you now possess a solid understanding of the various forms of industrial refuse that exist. This knowledge equips you to better assess and manage the waste produced in your own operations, thereby promoting a more sustainable and efficient approach. By recognizing the distinct characteristics and challenges associated with each type of industrial waste, you can implement effective strategies to mitigate environmental impact and ensure compliance with relevant regulations.

FAQ

Q: What is industrial refuse?

A: Industrial refuse refers to waste materials that are generated from industrial processes. This includes substances that are discarded during manufacturing, construction, processing, or other industrial activities. The types of waste can vary significantly based on the specific industry and the nature of the processes involved.

Q: What are the main types of industrial waste?

A: Industrial waste can be categorized into several types, including solid waste (such as scrap metal and packaging materials), liquid waste (such as chemicals and wastewater), and hazardous waste (such as toxic substances and flammable materials). Each category has different disposal and management requirements.

Q: How is industrial waste classified?

A: Industrial waste is typically classified based on its composition and characteristics. Common classifications include non-hazardous vs. hazardous waste, recyclable vs. non-recyclable materials, and biodegradable vs. non-biodegradable substances. This classification helps in determining the appropriate waste management techniques and regulations applicable to each type.

Q: What are the environmental impacts of industrial refuse?

A: The environmental impacts of industrial refuse can be significant and may include soil contamination, air pollution, and waterway degradation. Improper disposal or management of industrial waste can lead to harmful substances entering the ecosystem, affecting wildlife, human health, and overall environmental quality.

Q: How can industries manage their waste effectively?

A: Industries can manage their waste effectively by implementing waste reduction strategies, recycling materials, ensuring proper disposal methods, and adhering to regulatory standards. Conducting regular audits and assessments to identify potential waste reduction opportunities can further enhance waste management practices within an organization.

Q: Are there regulations governing industrial waste management?

A: Yes, industrial waste management is subject to various regulations enforced by local, national, and international authorities. Regulations may differ by region and typically address the generation, storage, transportation, treatment, and disposal of industrial waste to ensure safety and environmental protection.

Q: What role does recycling play in industrial waste management?

A: Recycling plays a significant role in industrial waste management by allowing materials that would otherwise be discarded to be repurposed and reused. This not only reduces the volume of waste sent to landfills but also conserves natural resources and minimizes environmental impacts. Many industries are encouraged to incorporate recycling practices into their waste management plans as a sustainable approach.