Management of industrial waste is evolving rapidly, and you need to be aware of the latest innovations that can dramatically improve your operations. With advancements in recycling technology and waste-to-energy processes, you can reduce your environmental impact while enhancing your bottom line. These innovations not only tackle the problem of hazardous materials but also promote a more sustainable future for industries. By staying informed, you can make choices that positively influence both your business and the planet.

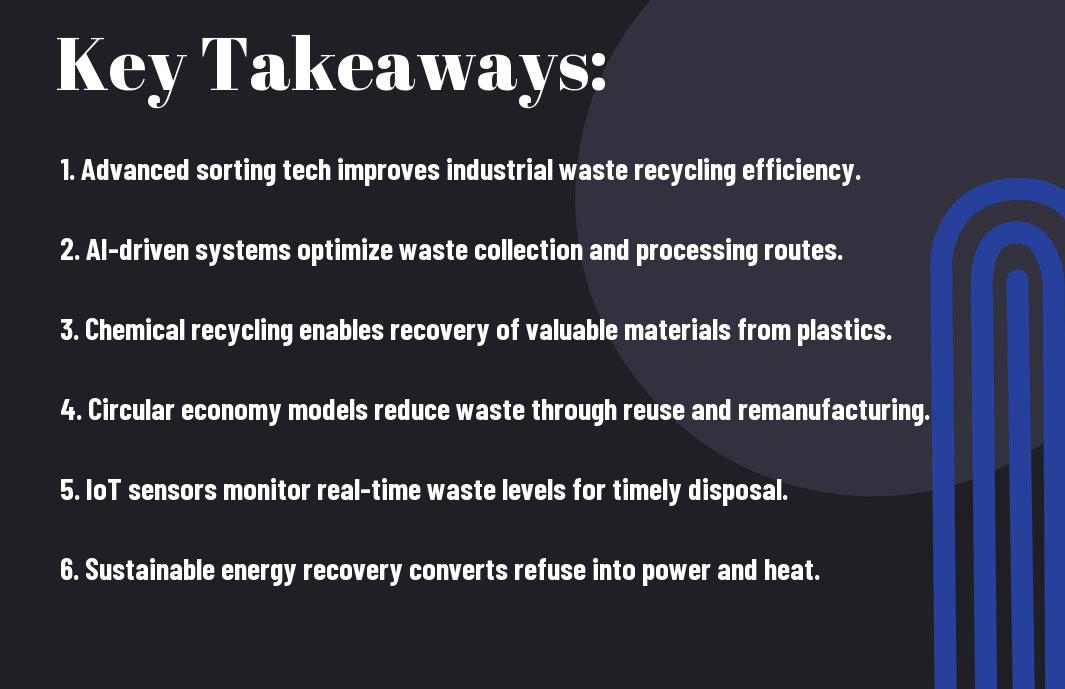

Key Takeaways:

- Emerging technologies such as AI and IoT are significantly enhancing waste tracking and management efficiencies within industrial settings.

- Waste-to-energy processes are gaining traction, allowing industries to convert refuse into usable energy, thereby reducing environmental impact.

- Circular economy practices are being increasingly adopted, encouraging businesses to recycle materials and minimize waste generation at the source.

- Collaboration between industries and waste management providers is pivotal for developing tailored solutions that improve waste handling and reduce costs.

- Regulatory frameworks are evolving to support innovative waste management practices, promoting sustainability and compliance among industrial sectors.

Decoding Industrial Waste: The Scale of the Challenge

Examining the Volume and Variability of Industrial Refuse

Industrial refuse encompasses a vast array of materials, varying widely in composition and volume. Each year, industries generate billions of tons of waste, with the most substantial contributors being the manufacturing, mining, and construction sectors. For instance, the manufacturing industry alone is responsible for about 7.6 billion tons of waste globally, and the types of waste produced can range from hazardous substances to recyclable materials, making effective management a daunting task.

Environmental and Economic Impacts of Neglected Waste Management

Failure to address industrial waste properly can lead to significant environmental degradation and economic consequences. Contaminants can leach into water sources, harming local ecosystems, while the loss of valuable resources can drive up costs for industries that rely on raw materials. When waste management practices falter, industries not only face fines and clean-up expenses but also damage their reputations and affect community health.

The implications of neglecting waste management extend beyond immediate environmental risks. Consider the textile industry, which discards about 92 million tons of fabric waste annually, much ending up in landfills. This not only wastes resources but also generates greenhouse gases during decomposition. Economically, your company could face increased operational costs due to fluctuating raw material prices, not to mention potential legal liabilities associated with environmental violations. By prioritizing effective waste management practices, you can mitigate these risks and contribute to a more sustainable future, ultimately benefiting both your bottom line and the planet.

Reinventing the Wheel: Breakthrough Technologies in Waste Processing

AI and Machine Learning in Sorting and Filtering Waste

Leveraging artificial intelligence (AI) and machine learning has transformed the efficiency and accuracy of waste sorting systems. By using image recognition algorithms, these technologies can distinguish between various materials at incredible speeds, greatly enhancing the sorting process. This means that recyclables are filtered from contaminants more reliably, leading to higher material recovery rates. As these systems learn from their sorting patterns, the potential to reduce human error and optimize operations continues to grow.

Advanced Recycling Techniques: From Trash to Treasure

Innovations in recycling are making it possible to repurpose materials that were once deemed too difficult or uneconomical to process. Techniques such as chemical recycling break down plastics into their original monomers for reuse. By converting waste back into raw materials, you can help close the recycling loop, minimizing the need for new resources. This transformation not only reduces landfill waste but also leads to a more sustainable circular economy.

- Chemical Recycling: Turning plastics back into raw materials.

- Bioleaching: Using microorganisms to extract valuable metals from electronic waste.

- Upcycling: Repurposing waste materials into new products with higher value.

- 3D Printing with Recycled Filaments: Utilizing waste plastics for additive manufacturing.

- Closed-loop Recycling: Ensuring materials are reused until they are no longer viable.

| Technique | Benefits |

|---|---|

| Chemical Recycling | Enhances plastic recovery and reduces dependency on virgin materials. |

| Bioleaching | Extracts valuable metals while minimizing environmental impact. |

| Upcycling | Creates unique products from waste, adding value and reducing landfill usage. |

By embracing these advanced recycling techniques, industries can not only minimize waste but also create innovative products. You may find yourself using goods made from recycled materials, contributing to a more sustainable environment. Additionally, technologies like 3D printing now allow for the use of recycled filaments, which further promotes sustainability. These approaches not only lower operational costs but also align with growing consumer demand for eco-friendly practices.

- Sustainable source reduction techniques to minimize waste generation.

- Integration of smart technologies in waste infrastructures for real-time tracking.

- Partnerships with local government and businesses to boost recycling rates.

- Encouraging community involvement in recycling initiatives.

- Establishment of testing centers for new recycling technologies.

| Industry Collaboration | Outcome |

|---|---|

| Partnership with tech companies | Enhances sorting efficiency and accuracy. |

| Engagement with NGOs and community groups | Raises awareness and boosts participation in recycling efforts. |

| R&D investment programs | Fosters innovation in recycling processes and technologies. |

Circular Economy: A New Paradigm for Industrial Systems

Closing the Loop: The Role of Sustainable Design

Sustainable design is an crucial component in closing the loop of the circular economy. By prioritizing materials that can easily be reused, recycled, or composted, you're not just minimizing waste; you're fostering an industrial culture that values resource optimization. This approach invites collaboration among designers, engineers, and manufacturers, pushing innovation in product life cycles while reducing the extraction of virgin materials and energy consumption.

Case Studies of Successful Circular Models in Industry

Several industries have adopted circular economy principles, showcasing impressive results in sustainability and resource management. Case studies illuminate how effective these models can be in championing a waste-free approach.

- Patagonia: This outdoor clothing brand has implemented a program encouraging customers to return used items for recycling, resulting in a 20% reduction in landfill waste.

- Interface: A global leader in modular carpet, it transformed its production processes to incorporate recycled materials, decreasing its greenhouse gas emissions by 96% per unit of product since the 1996 baseline.

- Renault: The automotive manufacturer has designed a plant focused on dismantling end-of-life vehicles, leading to a 85% recycling rate of vehicle components.

- Unilever: The company's initiatives to improve the lifecycle of packaging have achieved a goal of reducing waste by 50% by 2025, focusing on recyclable and biodegradable materials.

- Chivas Regal: This whisky brand repurposes its spent grains into packaging for other products, effectively closing the loop on its production waste.

Each case study highlights significant shifts toward sustainability. For instance, Patagonia's initiative not only streamlines waste management but also enhances customer loyalty through environmental responsibility. Similarly, Interface's transformative practices in carpet manufacturing serve as a powerful example of how innovation can lead to substantial reductions in carbon footprints, evidenced by a noted 96% emission reduction. Renault's dismantling operation not only improves recycling rates but also ensures that valuable materials are efficiently reclaimed, demonstrating the financial and environmental benefits of a circular model.

Transformative Innovations: Waste-to-Energy and Beyond

Exploring Biomass and Thermal Processing Techniques

Biomass and thermal processing techniques offer dynamic solutions for waste management, converting organic materials into energy. Through methods such as anaerobic digestion and gasification, your facilities can transform both agricultural residues and industrial byproducts into renewable energy sources. This not only minimizes waste but also promotes sustainability by harnessing the energy embedded within these resources, contributing significantly to reducing your carbon footprint in the industrial sector.

Examining the Role of Waste-to-Energy Plants in Reducing Landfill Dependency

Waste-to-energy plants serve as critical infrastructures within modern waste management systems, significantly lowering landfill dependency. By burning municipal solid waste, these facilities convert refuse into usable energy, which can power homes and businesses while simultaneously curbing the volume of waste that ends up in landfills. As you consider the trajectory of industrial waste management, these plants play a vital role by diverting *millions of tons* of waste annually from landfills, ultimately promoting a circular economy where waste is seen as a resource rather than merely refuse.

The impact of waste-to-energy plants extends beyond their immediate function. For example, in countries like Sweden and Germany, effective waste-to-energy systems have contributed to achieving landfill diversion rates exceeding *90%*. Such successes illustrate the potential for integrating renewable energy into your operations while addressing the growing waste crisis. By investing in waste-to-energy solutions, you not only improve waste management efficiencies but also align your operations with global sustainability goals, setting a precedent for future innovations in the field.

Smart Waste Management: The Role of IoT and Big Data

Real-Time Tracking and Analytics for Improved Efficiency

Integrating IoT sensors into waste management allows for real-time tracking of waste levels and collection schedules. These smart systems not only optimize routes for waste collection vehicles but also reduce operational costs by minimizing unnecessary trips. By analyzing data from various touchpoints, you can enhance efficiency and ensure timely responses to changing waste patterns, ultimately leading to significant operational improvements.

Predictive Maintenance: Forecasting Waste Generation Patterns

Utilizing big data analytics enables you to accurately forecast waste generation patterns, allowing for preemptive logistics planning and resource allocation. By continuously monitoring waste production across different sectors, predictive maintenance can streamline operations, reduce bottlenecks, and improve overall waste handling.

For instance, by collecting and analyzing data on historical waste generation trends, you can predict peak times for waste production in specific industries. Companies leveraging this approach have reported operational efficiencies of up to 30% due to optimized collection schedules and resource availability. Moreover, understanding these patterns helps identify potential areas for waste reduction initiatives, allowing you to minimize the environmental impact and maximize savings. As you invest in such predictive technologies, you're not just keeping pace with waste management needs; you're paving the way toward a more sustainable future.

Regulatory Evolution: Navigating the Policy Landscape

Understanding Compliance and the Changing Environmental Regulations

Staying compliant with evolving environmental regulations is a significant aspect of waste management that directly affects your operations. Regulations often change to address new environmental concerns, with authorities implementing tighter controls on waste disposal and treatment processes. Understanding these regulations is imperative, as non-compliance can result in heavy fines and operational delays. You must keep abreast of local, national, and international standards, as they shape the frameworks within which you manage industrial refuse.

Incentives and Support for Technological Adoption in Waste Management

Adopting advanced technologies for waste management is not just beneficial; it is often incentivized by governmental and non-governmental organizations. Many states and countries offer tax credits, grants, and reduced compliance costs for companies that implement sustainable practices and innovative waste management technologies. These incentives can significantly mitigate the initial costs associated with technology upgrades, allowing your facility to operate more efficiently and sustainably.

For instance, the U.S. Environmental Protection Agency (EPA) provides funding opportunities through programs like the Waste Management Innovation Grant. This program supports initiatives that showcase new methods of waste disposal and recycling, which you can tap into as a way to offset costs related to technological investment. Correspondingly, local governments may have specific incentives like streamlined permitting processes or funding for research and development in waste management, which can lead to significant operational improvements and cost savings for your facility. By actively engaging with these programs, you can enhance your waste management strategies while contributing to environmental sustainability.

The Human Element: Training a New Generation of Waste Managers

Bridging the Skills Gap: Educational Initiatives and Workforce Development

To effectively tackle the challenges in waste management, educational initiatives targeting the next generation of waste managers are necessary. Community colleges and vocational schools have begun integrating specialized waste management programs that offer hands-on experience and theoretical knowledge. Recent statistics show that equipping new workers with these skills can boost productivity by over 30%, while also improving compliance with environmental regulations. This tailored approach ensures that your workforce is not only knowledgeable but also adaptable to emerging technologies and methods.

Fostering Innovation Through Collaboration Among Industries

Collaboration among various industries is key to fostering innovation within the waste management sector. By pooling resources, knowledge, and expertise, companies can address pressing waste challenges more effectively. For instance, partnerships between manufacturers and waste management firms have led to the development of new recycling technologies, vastly improving material recovery rates and sustainability efforts. Such collaborations can reduce the carbon footprint of both parties involved, demonstrating a shared commitment to environmental stewardship.

One notable example is the collaboration between the automotive and recycling industries, which has resulted in innovative solutions for recycling automotive plastics. This partnership has yielded materials that can be remanufactured with up to 90% less energy compared to traditional methods. Additionally, shared research initiatives focused on waste-to-energy systems have unveiled significant cost-saving potential while creating sustainable sources of power. By working together, industries are not just tackling waste—they are paving the way for a more sustainable future.

Future Trends: Predicting the Next Frontier in Waste Management

Anticipated Developments in Technology and Infrastructure

Emerging technologies like artificial intelligence and robotics are set to revolutionize waste sorting processes, making them faster and more efficient. You can expect to see advanced sorting facilities with automated systems that can identify and separate recyclables from industrial refuse with unprecedented accuracy. Innovations in biotechnology can also support organic waste conversion into energy, minimizing landfill use and promoting a circular economy. The integration of these technologies will call for new infrastructure that supports smart waste management practices, optimizing logistics and resource recovery.

How Global Crises May Shape Waste Management Strategies Moving Forward

Global crises, like pandemics and climate change, significantly influence waste management strategies. You might see a shift towards sustainable and resilient practices, as industries face pressure to adapt to rapidly changing regulations and consumer expectations. Companies will likely invest more in waste reduction methods, focusing on minimizing environmental impact while boosting operational efficiency.

The upheaval brought about by global events emphasizes the relationship between public health and effective waste management. For example, during the COVID-19 pandemic, the increase in single-use plastics raised concerns about landfill burdens. Consequently, industries adapted by exploring sustainable alternatives and enhancing recycling programs. Furthermore, government initiatives now often prioritize waste reduction and resource recovery, fostering collaboration among businesses to share waste and leverage byproducts. As these trends evolve, expect your organization's waste management strategy to include more innovative, eco-friendly practices that respond to both environmental challenges and societal needs.

Conclusion

To wrap up, you can see that the future of waste management hinges on innovative solutions that address the complexities of handling industrial refuse. By embracing advanced technologies, such as AI-driven sorting systems and waste-to-energy conversion, you can significantly improve efficiency and sustainability in your operations. Staying informed about these advancements will empower you to make smarter decisions for your organization and bolster your commitment to environmental stewardship in an ever-evolving industrial landscape.

FAQ

Q: What are the latest innovations in waste management technology for industrial refuse?

A: Recent innovations include advanced recycling processes like chemical recycling, which breaks down plastics into their fundamental materials for reuse. Additionally, artificial intelligence (AI) is being employed to sort waste more efficiently and accurately. Waste-to-energy technologies are also gaining traction, converting refuse into renewable energy sources. Furthermore, robotics is being implemented to automate collection and sorting, enhancing efficiency in waste treatment facilities.

Q: How do smart waste management systems work in industrial settings?

A: Smart waste management systems utilize IoT (Internet of Things) devices to monitor and manage waste. Sensors are installed in waste containers to track fill levels, enabling optimized collection schedules and routes. Data analytics helps identify patterns in waste generation, allowing industries to make informed decisions regarding waste reduction and resource allocation. This leads to cost savings, reduced environmental impact, and increased efficiency in waste management operations.

Q: What role does sustainability play in the future of waste management?

A: Sustainability is at the forefront of modern waste management strategies. Industries are adopting circular economy principles, which aim to minimize waste through recycling and reuse of materials. By focusing on sustainability, companies can reduce their carbon footprints, comply with environmental regulations, and promote eco-friendly practices. Sustainable waste management not only benefits the environment but also enhances brand reputation and drives consumer loyalty.

Q: How are industries addressing hazardous waste management with new techniques?

A: Industries are implementing advanced treatment technologies such as plasma gasification and bioremediation to manage hazardous waste. Plasma gasification uses extreme heat to convert waste into syngas and slag, effectively neutralizing harmful substances. Bioremediation leverages microorganisms to break down contaminants in hazardous waste. Both techniques minimize risk to human health and the environment while ensuring compliance with regulatory standards.

Q: What strategies can businesses adopt to reduce industrial waste generation?

A: Businesses can implement several strategies to reduce waste generation, such as adopting lean manufacturing processes that minimize material use and streamline production. They can also engage in product redesign to use less packaging and recyclable materials. Additionally, employee training programs focusing on waste reduction practices can foster a culture of sustainability within the organization. Collaborations with suppliers for sourcing sustainable materials can further enhance waste reduction efforts.

Q: How can businesses measure the effectiveness of their waste management initiatives?

A: Businesses can measure the effectiveness of their waste management initiatives by establishing key performance indicators (KPIs), such as waste diversion rates, recycling rates, and the amount of waste generated per unit of production. Regular audits and assessments of waste management processes can provide insights into areas needing improvement. Utilizing software tools for tracking waste data can also help identify trends and inform decision-making.

Q: What are the expected challenges in implementing new waste management technologies in industries?

A: Implementing new waste management technologies may present challenges including the high initial costs of investment, potential resistance to change among employees, and the need for staff training on new systems. Additionally, industries may face regulatory hurdles or lack of infrastructure to support advanced waste management methods. Overcoming these challenges requires strong leadership, clear communication, and a commitment to operational transformation.