Hazards related to industrial waste can pose significant risks not only to your operations but also to the environment and public health. By implementing best practices for managing both hazardous and non-hazardous materials, you can mitigate these dangers effectively. This guide provides necessary strategies, including proper waste classification, employee training, and sustainable disposal methods, that will help you maintain compliance and promote a safer workplace. Understanding these practices will empower you to handle industrial waste responsibly, ensuring the protection of your team and surrounding community.

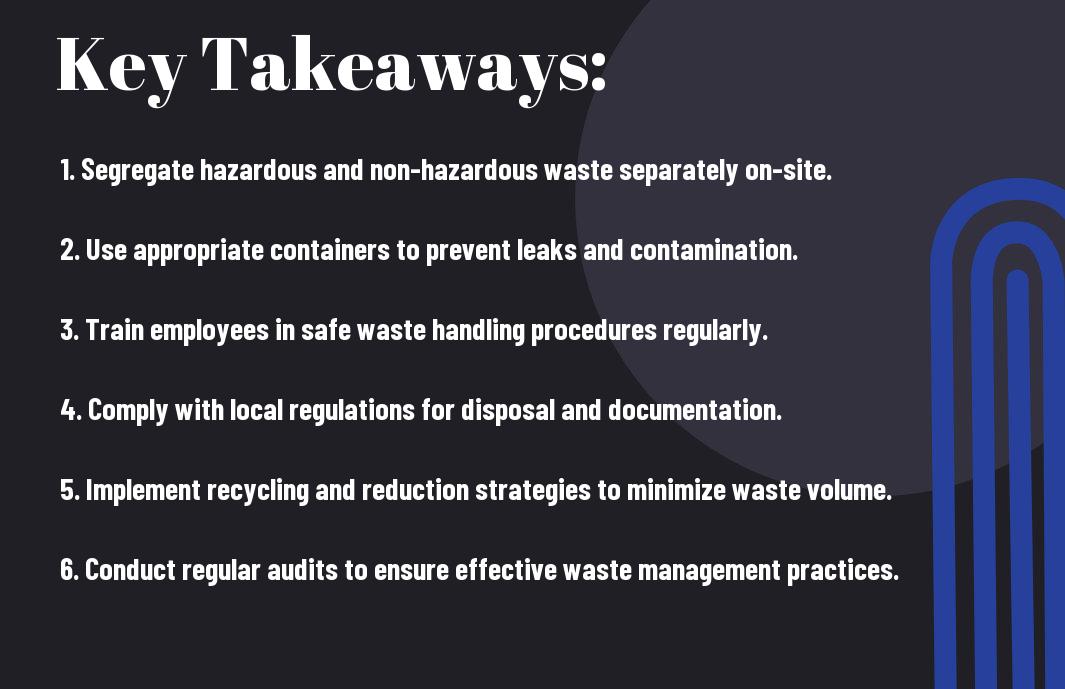

Key Takeaways:

- Implement a waste management plan tailored to the specific types of hazardous and non-hazardous materials generated by the facility.

- Ensure employees are trained in proper handling, storage, and disposal practices to minimize risks associated with industrial waste.

- Utilize appropriate labeling and signage to clearly identify hazardous materials and inform employees about necessary precautions.

- Regularly conduct audits and inspections to ensure compliance with environmental regulations and the effectiveness of waste management practices.

- Explore opportunities for waste reduction, recycling, and recovery to promote sustainability and reduce the environmental impact of operations.

The Regulatory Landscape: Navigating Compliance in Waste Management

Understanding National Regulations

Familiarizing yourself with national regulations is important for effective waste management. The Resource Conservation and Recovery Act (RCRA) governs the disposal of hazardous waste, presenting a framework that all industries must comply with. The Environmental Protection Agency (EPA) oversees these regulations, providing guidelines on waste classification, storage, and transportation. Non-hazardous waste is also regulated under various environmental laws, ensuring that disposal practices align with local and national standards.

State-Level Variations and Local Compliance

States often tailor their regulations to address specific environmental concerns, leading to significant variations in compliance requirements. You may find that your state has additional registration processes, reporting guidelines, or waste management initiatives that surpass federal standards. For instance, California enforces stricter regulations on hazardous waste; businesses must obtain a “hazardous waste generator permit” in addition to federal compliance. Not adhering to these local rules can lead to severe penalties.

Understanding these state-level variations is pivotal because non-compliance can result in financial repercussions and damage to your reputation. States may require special training for personnel handling hazardous materials, develop unique recycling initiatives, and possess their own definitions of what constitutes hazardous waste. Additionally, local regulatory agencies may conduct inspections and audits, further complicating compliance if you're unaware of specific local laws. Investing time in researching and establishing relationships with local environmental authorities can help you ensure compliance and promote a sustainable waste management strategy.

Identifying Hazardous vs. Non-Hazardous Materials: A Crucial Distinction

Defining Hazardous Waste Categories

Hazardous waste is classified into two main categories: listed and characteristicignitability, corrosivity, reactivity, or toxicity. Identifying these categories accurately is imperative for proper handling and compliance with regulations.

Grey Areas: When Does Waste Become Hazardous?

The distinction between hazardous and non-hazardous waste can often be ambiguous, especially in cases involving materials that are on the borderline. Waste may transition to hazardous status based on factors like concentration, chemical reactions, and environmental conditions. For example, non-hazardous waste that becomes contaminated with a hazardous substance may generate significant liabilities.

Understanding these grey areas requires careful analysis. For instance, a non-hazardous oily waste from machinery might become hazardous if it contains elevated levels of PCBs (polychlorinated biphenyls) above regulatory limits. Similarly, general waste containing quicksilver could shift in classification if mixed improperly. You must regularly evaluate your waste streams and maintain records in case of inspections or legal inquiries, ensuring compliance with hazardous waste regulations to avoid severe penalties.

The Lifecycle of Industrial Waste: From Generation to Disposal

Waste Generation and Initial Handling

Every industrial process generates waste, and the first step in managing it effectively lies in understanding its composition and volume. This stage involves the identification of materials being discarded, whether solid, liquid, or gaseous. Proper labeling, segregation, and containment at the source prevent cross-contamination and simplify further processing. For instance, facilitate the efficient collection of hazardous waste by using color-coded bins and ensuring your staff is trained to recognize these materials immediately.

Treatment, Storage, and Final Disposal Options

After initial handling, industrial waste typically undergoes various treatment processes to reduce its toxicity and volume, preparing it for safe storage or disposal. Methods such as incineration, landfilling, and recycling are common, with the choice depending largely on the waste's characteristics. It's vital to assess treatment options based on local regulations and environmental impacts.

Treatment is fundamental in minimizing the hazards posed by waste; for instance, incineration can significantly reduce the mass and volume of organic waste while generating energy. On the other hand, some materials may require advanced recycling techniques or chemical treatments to neutralize hazardous substances. Proper storage solutions are equally important, ensuring that waste is kept in secure containers to mitigate risks of leaks or exposure. Final disposal methods, such as designated landfills equipped for hazardous waste, play a vital role in safeguarding the environment and public health. Understanding the interplay between these stages enables you to implement effective waste management strategies, showcasing your commitment to sustainable industrial practices.

Best Practices for Hazardous Waste Management: Safety First

Emergency Preparedness and Response

Developing a comprehensive emergency preparedness plan is imperative for managing incidents involving hazardous waste. Identify potential risks specific to your operations, create response teams with designated roles, and regularly conduct drills to ensure everyone knows how to act quickly and effectively. Maintain an inventory of emergency supplies and ensure they are accessible, including spill kits, personal protective equipment (PPE), and communication devices to report emergencies promptly to appropriate authorities.

Employee Training and Safety Protocols

Regular training sessions on hazardous waste handling and safety protocols will significantly reduce workplace accidents. Ensure employees understand the classification of hazardous materials, their associated risks, and the proper procedures for managing spills or accidents. Providing access to updated safety manuals and simulations can reinforce their learning and enhance their capacity to respond effectively in critical situations.

Incorporating a structured training program into your operations can enhance employee readiness and compliance. Consider conducting quarterly workshops focused on specific materials, tailored training for different job functions, and refresher courses to keep information current. Leveraging case studies of past incidents can help illustrate the importance of safety protocols. Moreover, communication channels should be established for reporting near-misses and incidents, allowing continuous improvement of safety practices and fostering an environment of accountability.

Sustainable Strategies for Non-Hazardous Waste: Reducing, Reusing, Recycling

Implementing Effective Waste Minimization Techniques

To effectively minimize waste, you should adopt practices such as conducting regular waste audits and implementing lean manufacturing principles. This helps in identifying waste sources and eliminating unnecessary materials or processes. By optimizing production efficiency and adopting a circular economy approach, you can significantly reduce the volume of waste generated while enhancing operational performance and sustainability.

Innovative Recycling Programs in Industry

Adopting innovative recycling programs can transform your waste management strategy and contribute to sustainability. For instance, companies are repurposing scrap materials into new products, developing closed-loop systems that allow for the recycling of materials back into the production process. Such strategies not only minimize waste but also create new revenue streams and improve overall efficiency.

For example, a manufacturing firm in the automotive sector has implemented a program to recycle metal shavings generated during production. By processing these shavings back into raw material, the company reduced its waste by 30% and saved approximately $1 million annually in material costs. This proves that integrating innovative recycling programs not only fosters environmental responsibility but also drives financial performance, showcasing the dual benefits of adopting sustainable practices.

Technological Innovations: Tools for Effective Waste Monitoring

Smart Sensors and IoT in Waste Management

Smart sensors integrated with IoT technology revolutionize your waste management process by providing real-time data on waste levels and material types. These sensors can alert you when containers reach capacity or need servicing, effectively reducing collection costs and preventing overflow. For instance, cities like San Francisco are implementing smart bins that communicate directly to waste management systems, enabling optimized routes and reducing carbon emissions from waste collection vehicles.

The Role of Data Analytics in Streamlining Operations

Leveraging data analytics can transform your waste management strategies by identifying trends and inefficiencies. Utilizing analytics allows you to monitor waste generation patterns, enabling you to tailor your services and reduce costs. By analyzing data over time, you can optimize operations, ensure compliance with regulations, and enhance sustainability efforts within your organization.

Data analytics serves as a powerful ally in pinpointing specific waste generation trends and resource allocation inefficiencies. For example, identifying peak waste production times can help you schedule pickups more effectively and reduce service frequency during low-demand periods. With insights derived from data, you can assess the impact of recycling initiatives, adjust staff workloads, and identify areas where you can induce behavioral changes among employees or clients, ultimately driving down waste generation and increasing recycling rates.

Collaboration and Partnerships: Building a Waste Management Network

Engaging with Local Authorities and Organizations

Establishing a strong relationship with local authorities and organizations is vital for effective waste management. Collaborating with regional environmental agencies can provide access to necessary resources, technical assistance, and compliance information. Building partnerships with local non-profits and community organizations can also help you gain insights into community needs and facilitate informational awareness campaigns that promote responsible waste management practices.

The Importance of Industry Coalitions for Best Practices

Joining industry coalitions fosters collaboration that leads to the development of shared standards and best practices for waste management. By participating in coalitions, you can engage with peers facing similar challenges, share innovative solutions, and leverage collective bargaining power for better waste disposal contracts. These networks can also serve as platforms for training, allowing you to stay updated on the latest regulations, technologies, and sustainability practices.

For example, organizations like the National Waste and Recycling Association (NWRA) provide a collaborative environment where companies can exchange cutting-edge methods for waste reduction and recycling. Members report significant efficiency gains and cost reductions through the implementation of strategies shared during coalition meetings. The pooling of resources, knowledge, and experiences within such alliances not only enhances individual operations but also strengthens the broader industry's commitment to sustainability and regulatory compliance.

Future Trends in Industrial Waste Management: A Forward-Looking Perspective

The Rise of Circular Economy Principles

The adoption of circular economy principles is transforming the landscape of waste management in industrial sectors. Instead of a linear manufacturing model, where products are made, used, and discarded, a circular economy emphasizes reusing, refurbishing, and recycling materials. This shift not only minimizes waste but also reduces the demand for new raw materials, leading to significant cost savings and environmental benefits. Industries are increasingly designing products with the end of their life cycle in mind, enabling you to extract maximum value from your materials.

Anticipating Regulatory Changes and Technological Advances

Staying ahead of regulatory changes and integrating emerging technologies will define successful waste management strategies in the future. As global attention toward sustainability grows, anticipate stricter regulations that will require your company to adhere to more robust waste management practices. Embracing innovative technologies, like advanced data analytics and automation, can not only streamline your processes but also ensure compliance with evolving standards.

For example, the European Union has proposed several new regulations targeting landfill waste and the management of hazardous materials, aiming to reduce overall waste generation by 50% by 2030. In tandem, advancements in machine learning and artificial intelligence enable you to analyze waste streams more efficiently, identifying recyclables and hazardous components with greater accuracy. Adopting these technologies not only prepares your operations for future compliance but also positions your organization as a leader in sustainability within your industry. By proactively adapting to these changes, you not only safeguard your business but also contribute to a healthier planet.

Conclusion

Summing up, effective management of industrial waste, whether hazardous or non-hazardous, relies on your commitment to best practices. By implementing proper storage, identifying waste types, adhering to regulations, and training staff, you can significantly reduce environmental impact and enhance workplace safety. Consistently evaluating and improving your waste management strategies will not only benefit your organization but also contribute positively to the community and ecosystem. Take proactive steps now to ensure sustainable and responsible waste handling in your operations.

FAQ

Q: What are hazardous materials in industrial waste, and why is it important to manage them properly?

A: Hazardous materials in industrial waste include substances that can pose risks to health and the environment, such as chemicals, heavy metals, and certain biological waste. Proper management is crucial to prevent spills, accidents, and contamination of air, water, and soil, ensuring safety for workers and surrounding communities.

Q: What are the best practices for identifying hazardous waste in an industrial setting?

A: Best practices for identifying hazardous waste include conducting thorough assessments of materials used in processes, utilizing safety data sheets (SDS) to understand potential hazards, training staff to recognize waste types, and implementing regular waste audits to keep track of waste categories and volumes.

Q: How can non-hazardous materials be effectively managed to minimize waste?

A: Non-hazardous materials can be effectively managed through practices such as source reduction, recycling, reusing materials, and optimizing production processes to reduce excess. Implementing an inventory management system helps minimize over-ordering and waste generation, as well as educating employees on best practices for waste reduction.

Q: What regulations should be considered when managing industrial waste?

A: When managing industrial waste, it is important to consider local, state, and federal regulations. This includes the Resource Conservation and Recovery Act (RCRA) for hazardous waste, Environmental Protection Agency (EPA) guidelines, and any specific state regulations. Compliance ensures safe handling, treatment, and disposal of waste materials.

Q: What steps should be taken to train employees on industrial waste management?

A: Training employees on industrial waste management should include comprehensive sessions on waste types, proper handling procedures, emergency response plans, regulatory compliance, and best practices for waste reduction. Regular refreshers and updates on current regulations and procedures will enhance workforce awareness and safety.

Q: How can an organization track its waste management efforts and measure improvements?

A: Organizations can track their waste management efforts by implementing a waste tracking system that records the types, volumes, and disposal methods of waste generated. Regular reporting and analysis of waste data help identify trends, set improvement goals, and measure progress over time. Utilizing software tools can aid in simplifying data collection and analysis.

Q: What role does technology play in enhancing industrial waste management practices?

A: Technology plays a significant role in enhancing industrial waste management through advanced monitoring systems, waste sorting technologies, and optimized disposal methods. Implementing automation can improve accuracy in tracking waste, while data analytics can help identify inefficiencies and areas for improvement in waste management practices.